SSA – next generation metal separation

get the most out of your existing potential.

The next level of metal separation.

REDUCTION IN PERSONNEL EXPENSES / MINIMIZE THE REFUSAL AT STEEL MILL / IMPROVE SEPARATION EFFICIENCY

MS-14/57

The next level of metal separation.

Reduction in personnel expenses

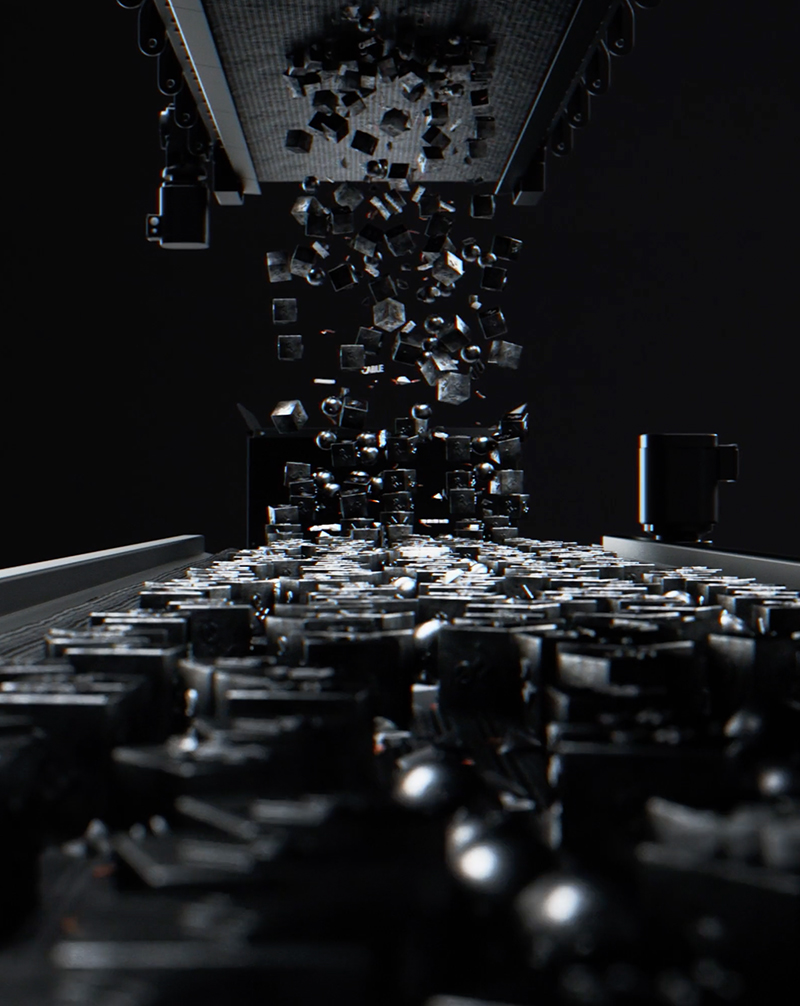

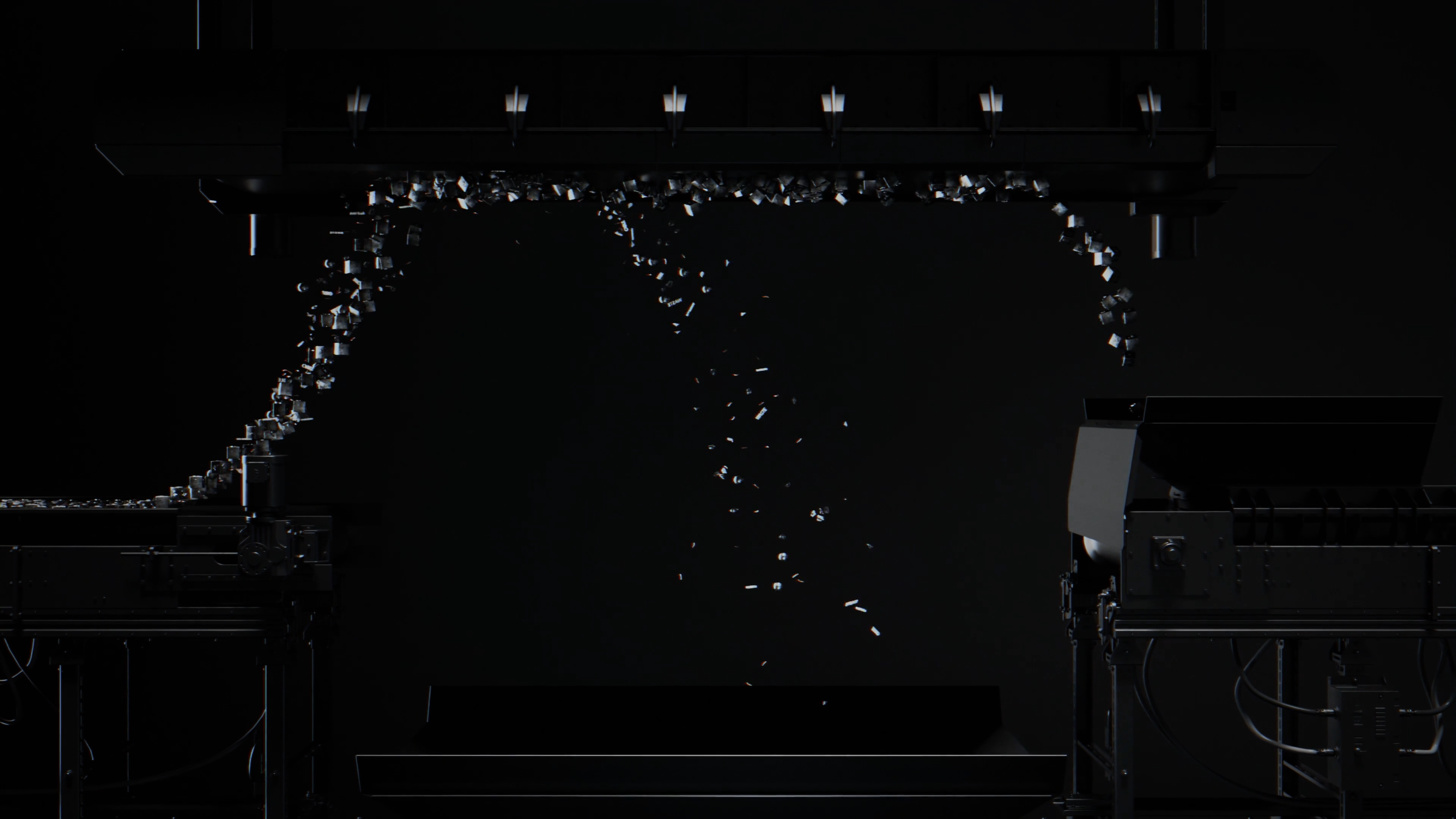

Following the magnetic drum separation loose parts within non-magnetic fraction ( non-ferrous metals/waste) are separated by an innovative mechanical process

Improve the hand-screening efficiency

Manual picking is focussed on non-ferrous metals (armatures)

Low energy consumption of our seperator MS-14/57

Only – 15 KW energy consumption

Minimize the refusal at steel mill and blast furnace

Automatically screened fraction is a high quality heavy fraction (increased contribution margin)

MS – 14/57

Technical Data

| Weight | ca 23,810 lbs |

| Power input | 2 x 7,5 kW |

| Length rolling band | appr. 224 in |

| Length | appr. 2,186 – 2,299 in |

| Width | appr. 100 in |

*The plants efficiency depends on the source material. We are glad to show you the possibilities for your company.

MS – 14/57

Witness the power of our new separator.

With pleasure we persuade you of this plant’s effectiveness.

GET IN TOUCH

Europe

SSA GmbH

Spinnereiinsel 3a

83059 Kolbermoor

Germany